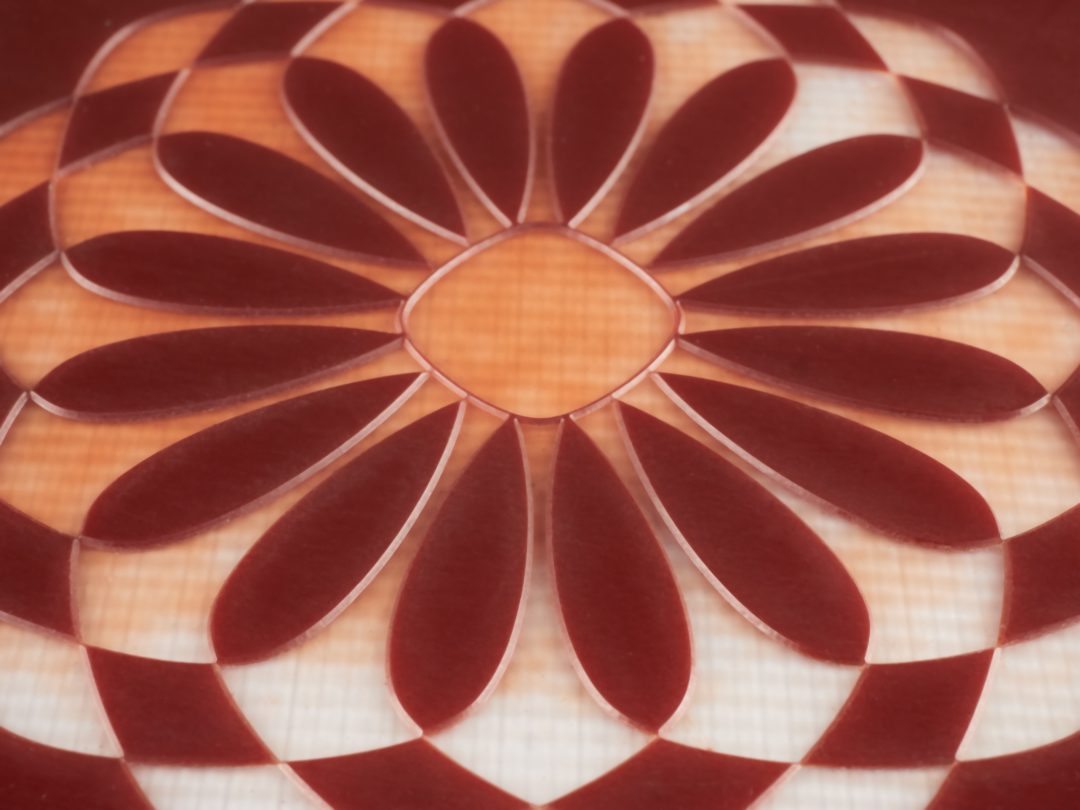

Debossing is the process of stamping an image or text into a chosen substrate resulting in an luxurious and tactile indented impression - the exact opposite of the embossing process.

Debossed finishes can be found on bound book covers, leather goods and plastics and are also ideal for drawing attention to brand names and logos when applied to paper and card to illustrate quality.

Tomlinson’s manufacture debossing dies in both magnesium and brass depending on their unique application. Our deep-etched magnesium debossing dies are a cost-effective solution for shorter production runs, whereas our brass dies are recommended for longer runs and/or harder substrates.

Below: Resin deboss counterforce; CNC tooling; brass deboss die.

Counterforces

Where debossed finishes are to be applied to lighter paper or card stock, a debossing counterforce will be needed.

Our Resin Counterforces consist of a robust glass-reinforced epoxy board onto which a tough, heat-resistant polyurethane polymer is cast to create a mirror-image of the die.

Resin counterforces can be manufactured with a base thicknesses of 0.4mm, 0.6mm and 0.8mm.

Learn more about our counterforces here and to see examples of debossed finishes achieved using Tomlinson’s high-quality dies, simply visit our gallery.

Magnesium Size and Gauge Guide

Tomlinson Ltd can produce magnesium Debossing Dies in a range of thicknesses and sizes to suit your needs.

Standard Gauges: 1.63mm, 4mm, 5mm, 6.35mm and 7mm

Maximum plate size: 610 x 914mm

Brass Size and Gauge Guide

Tomlinson Ltd can produce brass Debossing Dies in a range of thicknesses and sizes to suit your needs.

Standard Gauges: 4mm, 5mm, 6.35mm and 7mm, however brass dies can also be machined to other bespoke thicknesses so please just let us know your needs at the time of ordering.

Maximum Plate Size: 730mm x 510mm