Ginger Singh-Kauldhar

A Major Step Forward in Magnesium Production

As we head into the festive season, we are delighted to share one of our most exciting advancements of the year. Our magnesium department has just taken a significant step forward with the installation of our third etching bath. This investment gives us both flexibility and increased capacity to meet our customer’ deadlines while maintaining the quality you expect from Tomlinson.

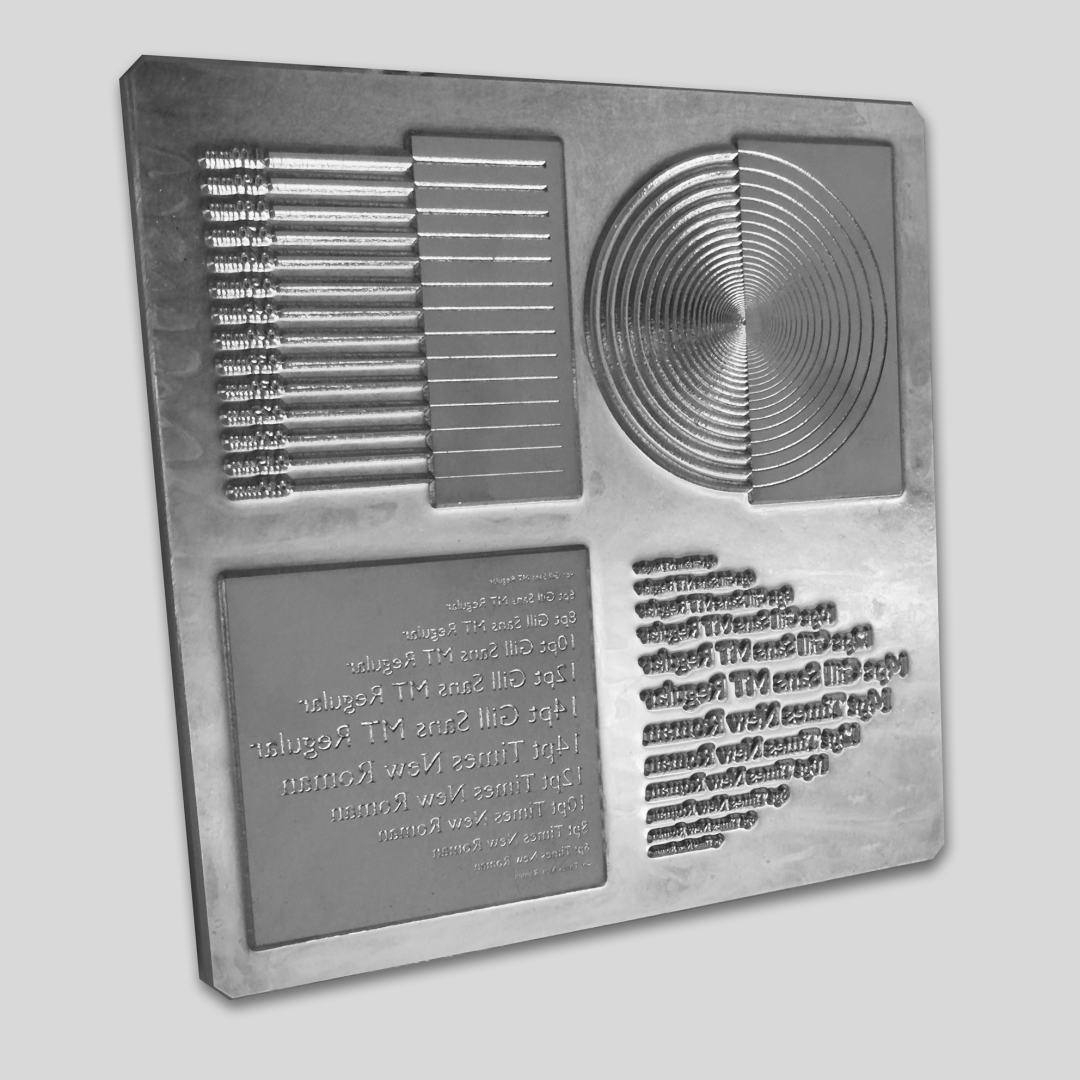

Magnesium has long been a cornerstone of our business. With the addition of our second Lüscher imaging system, modern technology has transformed what’s possible. Today’s magnesium, paired with direct-to-plate imaging, depth-controlled etching, and quality control, delivers fine detail and consistent results.

At Tomlinson, we continually explore new technologies, invest strategically, and automate processes where it improves efficiency, because precision, innovation, and care are at the heart of everything we do.

It’s worth noting that we are often cherry-picked for intricate jobs. Customers sometimes say:

“You don’t want my standard Magnesium flat foil or emboss orders!”

But as this article shows, even the simpler orders require care, expertise, and attention to detail to achieve the best results.

The Difference is in the Detail

Our customers often tell us how challenging it can be to achieve fine foiled detail or a decent emboss. One recent project involved a delicate crest originally etched in copper, which did not meet expectations. We recommended magnesium. Hesitant at first, the customer trusted our advice, and the result was described as:

“The best quality crest we’ve ever foiled.”

With shorter run lengths and fewer repeat jobs, more customers are now choosing magnesium for commercial print, books, stationery, packaging, and prototypes.

“While we are often selected for intricate work, magnesium remains an important part of our business. From simple flat foil orders to complex cut-flat, fluted, or textured designs, each project receives the same care and attention.”

- Ginger Singh, Business Development Director

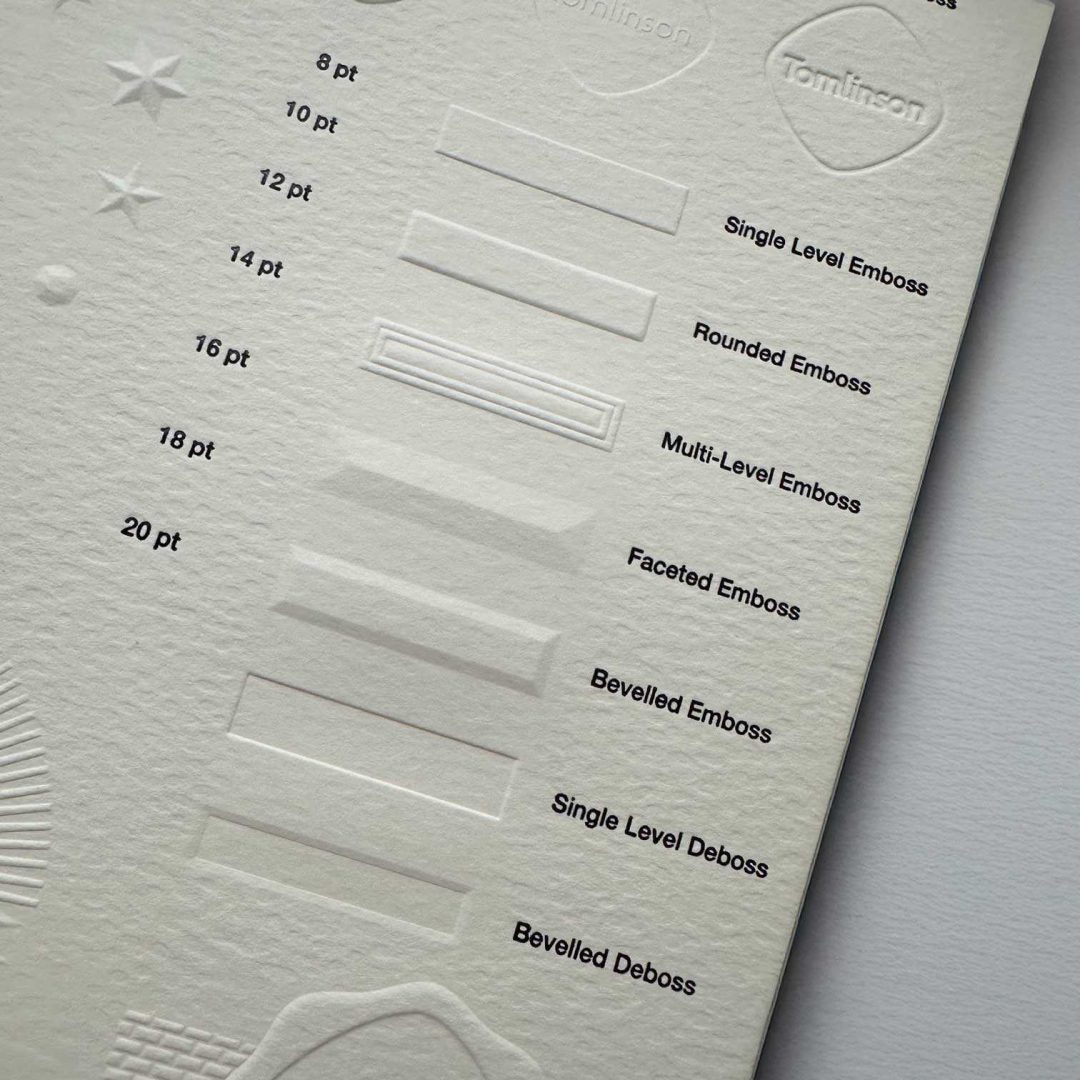

Perfecting Every Emboss

Are you finding that the emboss depth isn’t quite right, or that the final result falls short of expectations? Is the material marking or creasing, or are the edges cutting through the substrate because the shoulders of the die are too sharp?

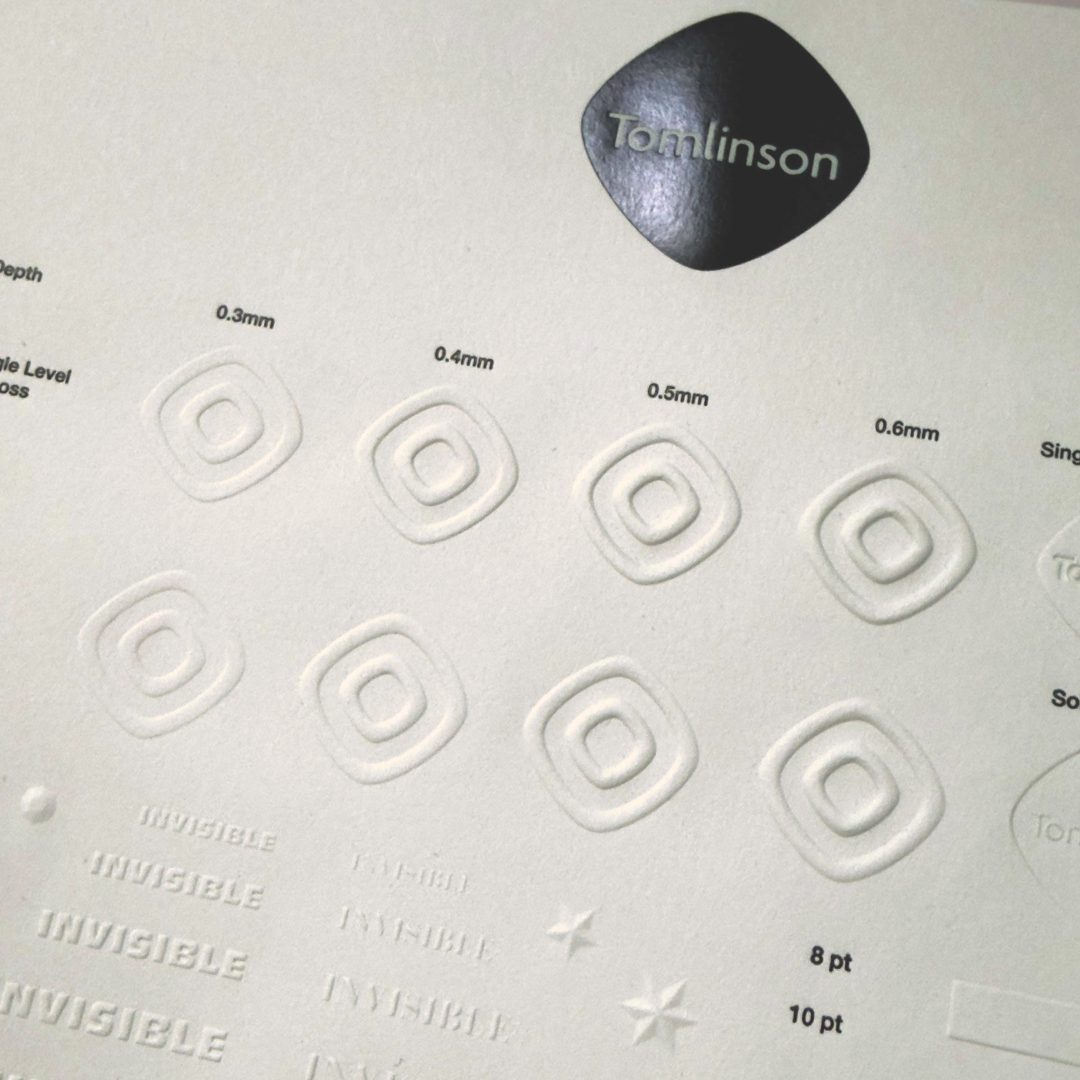

At Tomlinson, every emboss die is carefully etched to match the thickness of the customer’s material, maximising the emboss depth for the chosen substrate. Instead of applying a uniform depth across all dies, we customise our etch depths for its intended material. Whilst this process takes more time and thought, opposed to grouping multiple designs onto a single plate, it ensures the best possible result for your project.

For example, if an emboss die is being produced onto 120gsm paper, we determine the ideal etching depth from our experience, considering the image and substrate, rather than grouping images onto one large sheet of magnesium and using a depth suitable for a 300gsm card. Cutting corners is not how we operate, it’s our care, experience and attention to detail that truly makes the difference.

Our team ensures the shoulders are nicely rounded and every die is finished to prevent marking and these processes ensure an improvement in the overall emboss. Every die is made bespoke, ensuring your specifications are met without compromise. Overall, it’s about doing what’s right for our customers and building confidence that encourages repeat business and long-term relationships.

Key Information

- Material grammage in gsm and microns

- Whether the emboss fits a print, embossing over print is more forgiving; blind embosses rely solely on the embossing to reproduce the image

- The machine you’ll be using, to determine male counterforce thickness

- Any sample you’re trying to match, which is often only noticed after the job. Frequently, once an impression is taken, the customer calls to say the emboss doesn’t match the sample!

Providing these details allows us to deliver dies that meet your expectations.

Balancing Fine Detail and Bold Design

Jon Colburt, Production Director at Tomlinson, explains over the years, we have conducted extensive tests to understand the correlation between, substrates, image thickness and optimal etching depths.

A common challenge arises when a design combines bold elements with fine text underneath:

- Too deep on bold areas - fine text may not emboss fully

- Too shallow for fine text - bold areas lose depth

The ideal approach is to balance the depth, to ensure larger elements align closely with fine details. Producing a harmonious emboss overall. Though it may not achieve the deepest possible emboss, the process ensures uniformly across the entire image.

If artwork is too fine, we can suggest adjustments such as thickening fine areas, removing some artwork, or focusing on bolder elements. These early conversations avoid delays and reworks, ensuring a smoother process and better final results. Clear communication with our customers from the outset is key. Managing customer expectations upfront is fundamental, as we invoke our expertise in every element of your project.